Call Us Now

Mon - Sat

9 AM - 6 PM IST

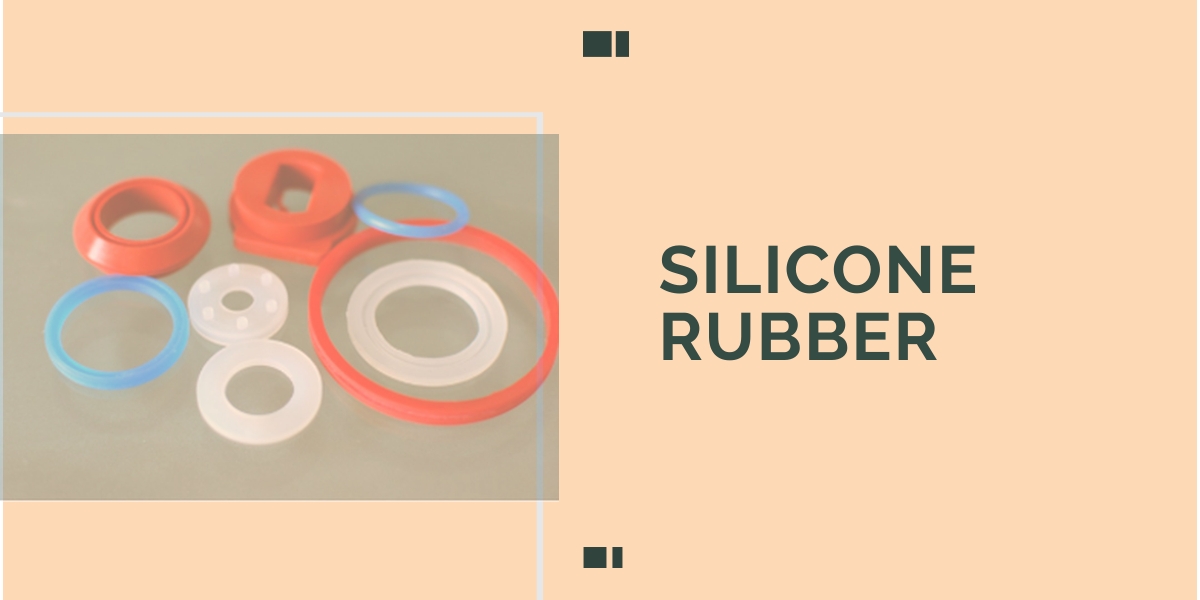

Silicone rubber is a synthetic elastomer with great properties such as elongation, high tear strength, good thermal conductivity and resistance to high temperature. It can be molded to O rings, gaskets, seals and to any custom shape. Silicone seals and gaskets are majorly used in industrial, automotive, medical, solar and food grade applications due to its exceptional properties. They can be used in extreme environments and temperatures from -100 °C to +300 °C. Silicone rubber will be available in hardness ranging from 20-80 SHA and can be molded in transparent and bright colors.

In medical devices and pharmaceutical applications, silicone rubber is used because of its biocompatibility in a wide variety of physical forms. Silicone rubber is also highly inert. Due to this remarkable property, it is used in many medical applications.

Used in electronic devices, it covers the inner circuit and processors to shield them from conditions that causes wear and tear. Silicone seals are ideal for solar panels and photo voltaic applications because of their exceptional resistance to Ultraviolet radiations.

Silicone has longer service life in adverse environments unaffected by rain, snow, ozone and UV rays.

When should silicone rubber be used?

- When your product needs to withstand extreme temperatures

- When you want the rubber part to exhibit low chemical reactivity

- When you need to work with food applications because silicone is a very safe polymer with no toxic effects

Disadvantages of Silicone rubber

- Expensive than other rubber compounds

- Poor resistance to steam and super heated water

- Not suitable for environments where silicone comes in contact with oil fuels and solvents